Your cart is currently empty!

Coffee Processing

Quality coffees must be picked by hand, a process that takes from three to four visits per tree each year. This is because coffee cherries do not ripen at the same time. A branch of a tree might simultaneously bear blossoms, green fruit, and ripe cherries. A good picker can pick about 200 pounds of coffee cherries in one day. This equals about 33 pounds of green coffee beans, which yields about 27.5 pounds of roasted coffee.

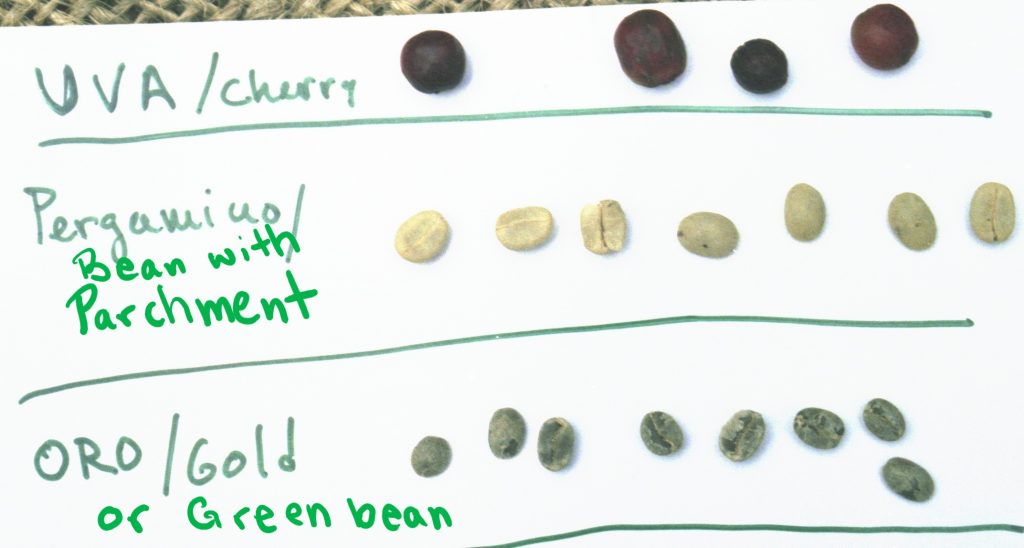

Once the coffee cherries have been picked, the beans must be removed from them. Then the beans are put through one of two processes: “Sun-dried” or “Water-processed. The terms “Sun-dried” and “Water-processed” refer to the method used to process the coffee bean prior to roasting.

Difference between Sun-dried and Water processed coffee:

The key difference is that the “Special Sun-dried” beans (also called Enmielado or Honey Coffee) has a very smooth flavor compared to the “Water-processed” beans, which tend to be more bold. These differences apply even when beans from both processing methods may have the same level of roasting. The “Special Sun-dried” process achieves a balance of smoothness and robustness in combination with low acidity.

Read on to learn more about the details of each processing method!

Sun Dried Method

In the “Special Sun-dried-Process” once the beans are split from the cherry, they are laid on screen frames above the ground to dry with the fruit juices (called miel del café) on the beans. They are moved constantly until the bean inside dries to a humidity between 12-13%. Because we use 150 pounds of cherries per screen, the amount of sun-dried coffee we can produce is limited. Typically, we produce between 300-400 pounds of green coffee through this process each year.

The beans are then removed from the parchment (a thin membrane surrounding the bean) to prevent rot, because the juices on the parchment will reabsorb water easily. Removing the parchment from these beans is time-consuming because of the sticky nature of the dried juices, which makes this process more labor-intensive.

The green beans are then put in special bags, called “Grain Pro”, that keep humidity out by vacuum sealing. The beans are then stored until we are ready to send them for roasting.

Water Process

In the “Water Processed” method, the beans are also mechanically split from the cherry, but afterwards are put in water tanks and ferment them overnight (maximum 12 hours) to loosen the fruit juices. We then rinse them well with water, before laying them out to dry on screens above ground. Because we have removed the juices and are not worried about fermentation, we can put the beans in thicker layers on the screens, which allows us to process more beans per year. Typically, we produces 2500-3000 pounds of green coffee through this process each year.

The beans are dried with the parchment covering until they reach 12% humidity. They are then removed from the parchment, which is less labor-intensive since they aren’t as sticky, and stored in vacuum sealed bags until roasting.